Properties:

Low thermal conductivity

Low electrical conductivity

Good weatherability

Ignition resistance, Chemical resistance

Wide range of colours, including clear grades

Cost efficiency is apparent due to versatility of applications

Typical applications:

Window frames, pipe, trims, automotive accessories, ticket molding for point of sale, merchandizing displays

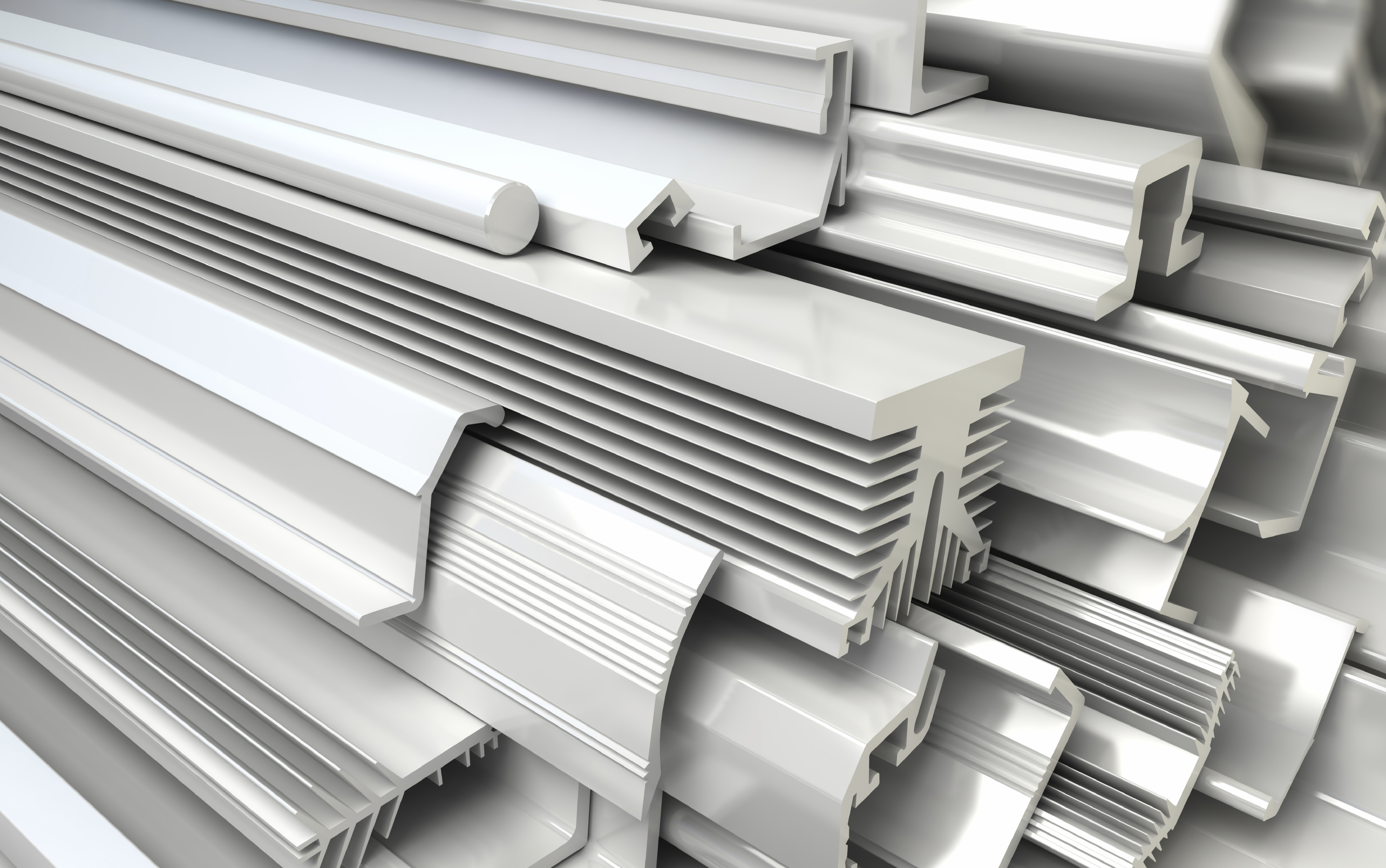

Rigid PVC

Properties:

Available from very soft to semi rigid

Wide range of colours,

Good weathering

Typical applications:

Gaskets, bumpers, flex trims, T-edges, tubing, weather-stripping

Flexible PVC

Properties:

Excellent chemical resistance

Nontoxic

Ductile at very low temperatures (-60C)

Typical applications:

Pipe and tubing, automotive accessories, protective trims, and profiles

Polyethylene

Polyethylene is one of the most widely produced plastics in the world. It comes in a variable crystalline structure that gives the material a wide range of physical characteristics. Generally, as the crystallinity increases the density classification increases. The higher density material becomes more stiff and rigid.

EVA – Ethylene Vinyl Acetate: Soft Pliable – Packaging, electrical wire and automotive parts

LLDPE – Liner Low Density Polyethylene: Packaging tubing

LDPE – Low Density Polyethylene: Packaging, tubing, and pipe

MDPE – Medium Density Polyethylene: Electrical, tubing, and pipe

HDPE – High Density Polyethylene: Tubing, pipe, profiles, protective trim

Properties:

Fatigue Resistance

Dimensional stability

Resistance to compression set

Heat aging stability

Low Temperature flexibility

Excellent U.V. and Ozone stability

Typical applications:

Weather stripping, seals, glazing boots for window seals, commercial glazing gaskets

TPE

Properties:

Two hardness – rigid spline with softer flexible fins

Two colours are possible

Cost reduction

Typical Applications:

Weather stripping, T-based slide in gaskets, hinges, glass tracks

Dual-Durometer PVC

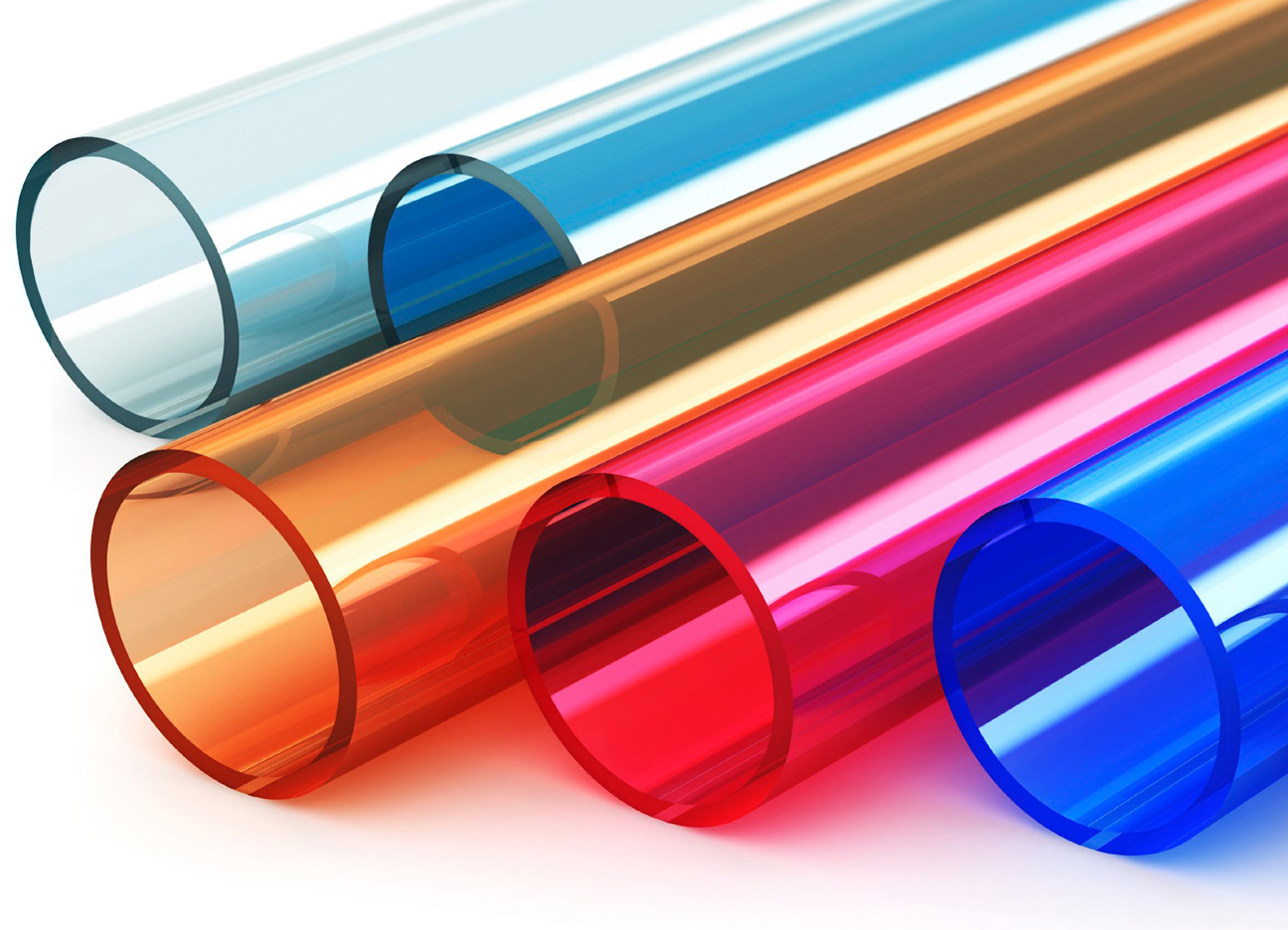

Properties:

Excellent Impact Resistance

Exceptional light transmission

Environmental Stability

Easily coloured

Good chemical resistance

Good U.V. resistance

Typical Applications:

Lighting applications (fixtures), sign applications, pipe

Acrylic

Properties:

Superior toughness

Excellent clarity

Good U.V. characteristics

Typical Applications:

Light diffusers, merchandising displays, automotive, packaging

Polycarbonate

Polycarbonate is durable, moldable, and lightweight and is shatter proof. Although made commercially available in a variety of colors, the raw material allows for the internal transmission of light nearly in the same capacity as glass. Polycarbonate polymers are used to produce a variety of materials and are particularly useful when impact resistance and/or transparency are a product requirement (e.g. in bullet-proof glass).

PC is commonly used for plastic lenses in eyewear, in medical devices, automotive components, protective gear, greenhouses and exterior lighting fixtures. Polycarbonate also has very good heat resistance and can be combined with flame retardant materials without significant material degradation.

Properties:

High rigidity

Excellent impact strength

Good chemical resistance and electrical insulation properties

Typical Applications:

Pipe, packaging, refrigerator liners, conduit

ABS

ABS is derived from acrylonitrile, butadiene, and styrene. The most important mechanical properties of ABS are impact resistance and toughness. A variety of modifications can be made to improve impact resistance, toughness, and heat resistance. It is widely used for machining pre-production prototypes since it has excellent dimensional stability and is easy to paint and glue.